a)

Priorities Selecting Quarries:

The quarries have been selected based on available data from

each of provinces and technical characteristics like minable

reserves, current rate of exploitation, rock types, color,

composition and quality.

The following minimum annual rates of production is used to

categorize different quarries considered in this Atlas:

• Altered marbles and porcelain 10,000MT

• Travertine 5,000MT

• Marble 2,000MT

• Granite 3,000MT

b)

Sampling:

Sampling has been carried out by groups of senior geologists.

All attempts are made to take a representative samples from

these quarries.

c)

Reserve estimation:

One of the key factors in investment related decisions is

assurance about the availability of mine reserves. For this

purpose, recorded numbers in exploitation licenses were

selected.

d) Evaluation of

exploitation:

The real production rate can be limited due to geological

constraints and involvement of unqualified people as managers.

For example, in most cases, methodology for mine management

applied does not meet minimum requirements of applicable global

standards utilized in the mining section. Due to lack of

management expertise and experience, even by having necessary

exploitation equipment. they are unable to increase their

production rates from minimum amount included in their original

mining license.

e)

Preparation of schematic sections:

Since, one of the main reasons of Atlas is to make

possibilities for participation, cooperation and exploitation of

foreign or local private sectors , so datas such as current and

existing exploitation conditions, tectonic situation, morphology

of materials which plays an important role in selection of the

equipment has been gathered by use of a schematic sections .

f)

Microscopic studies:

Since, the main and subsidiary minerals although is effecting

a rock from points of colour and quality view,but also is a main

determinant of applied consumption.

For example, the low oxide – mineral rocks have more constancy

in color. Therefore the microscopic studies were necessary.

g)

Lab selection and equipping:

In order to meet ASTM codes for physical and mechanical

behaviour of quarry stones, we did our tests in laboratories of

“The Construction Research Center”which would meet the needed

standards .

h)

Reliability of tests:

To meet ASTM standards, the confirmation of one international

standard institute was necessary. The Industrial Research

Institute of Iran has obtained all the required approvals for

the equipments.

i)

Mechanical tests:

All mechanical tests including sample preparation and methods of

measurement were carried out as follows:

Sample preparation: Taken

samples from the quarries have been cut in cutting workshops and

sent to the laboratories for tests. ASTM standards are

considered during sampling as shown in the following table.

Quantity and size of samples based on ASTM standards

|

No. |

Type of test |

Number of samples |

Size of samples (mm) |

|

1 |

water absorption |

Min. 3 samples, without layers |

Rectangular cubic, with min. 51 and max. 75 |

|

2 |

specific density |

Min. 6 samples with layers |

Rectangular cubic, with min. 51 and max. 75 |

|

3 |

Compression test |

5 samples for testing parallel and perpendicular to

layer |

Rectangular cubic, with min. 51 and max. 75 |

|

4 |

Module of elasticity |

3 samples,without layers, perpendicular to layers 3

samples and 3 samples alongside of layer |

Rectangular cubic, 102x204x57 |

|

5 |

grinding test |

3 samples |

Rectangular cubic, 26x51x51 |

|

6 |

bending test |

3 samples |

Rectangular cubic, 300x38x25 |

Based on standard codes, physical and mechanical tests should be

done in each sample and mean value of tests should not be

exceeding than 10%.

In addition to the prepared samples, we also prepared sample

with the dimentions of 2×10×10 cm for presenting the polishing

state so,the pictures of all the mines are based on their real

sizes .

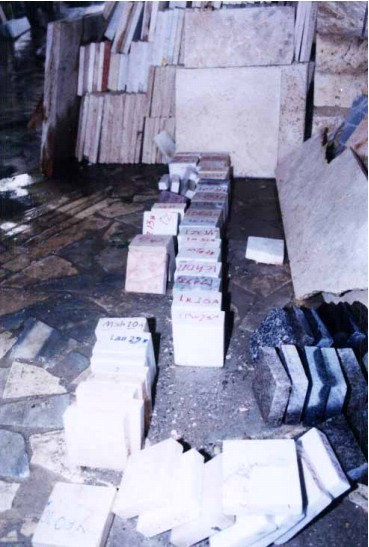

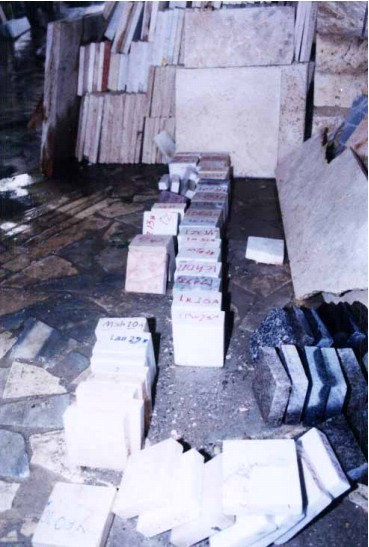

Methodology of Preparation of Samples for lab tests

Samples Prepared from Quarries

Setting the Samples on the Pallet under Cutters

Cuting the Samples

Classification of the samples

Samples laging of each mine

Samples Coding & Packaging for dispaching to lab

Regarding the standard methodology for measurement of physical

and mechanical specification , each sample should be tested in

several times . The mean value of the tests if not distorted

more than 10% , determined as the result . Other wise , the

sample should be reprepared and repeating the tests .

j) Methodology of Selecting

Scientific name of Stones :

To prevent various names of stones which uses in different

classifications , we determined the Dunhan System for notation

of sedimentary stones and regarding the volcanic stones ,we

cosidered the main and subsidiary materials and also the tissue

of the stones .

Based on obtained results from these tests all decorative stones

mentioned here, can be divided into four groups as follows:

Granite group:

Generally,and by definition

granite is a volcanic rock, which consist of quartz and feldspar

grains. Granite color varies from pink to gray with homogeneous

texture. Usually, one or several mafic minerals associated with

granite. In addition, some other volcanic rocks with mafic

features dubbed as granite, however, lithologicaly they cannot

be categorized as granite rocks.

Specification of granite decorative stone is shown in below

table based on ASTMC615-96.

|

Physical & Mechanical

spec. |

quantity |

Method of test |

|

Maximum water absorption (wt.%) |

0.4 |

ASTMC97-96 |

|

Minimum spg. (kg/m³) |

2560 |

ASTMC97-96 |

|

Minimum compression (Mpa)

|

131 |

ASTMC170-90(Reapproved1994) |

|

Module of elasticity(Mpa) |

10.34 |

ASTMC99-87(Reapproved1993) |

|

Min.

grinding (hardness) |

25 |

ASTMC241-90(Reapproved1997) |

|

Min.

bending stress (Mpa) |

8.27 |

ASTMC880-96 |

Limestone group:

Limestone is sediment rock

consisting of calcium carbonates (calcite minerals) or

calcium-magnesium (dolomite) or both of these minerals. In the

market of decorative stones, polishable re-crystallized

limestones, dense microcrystalline limestones and travertine’s,

are considered as a marble. Based on ASTM standard these rocks

can be categorized as a limestone or marble.

According to ASTM standards, decorative limestones are

classified based on their specific gravity into three groups:

1) Low density limestone – density between 1760 to 2160 kg/m³

2) Medium density limestone – density between 2160 to 2560

kg/m³

3) High density limestone – density more than 2560 kg/m³

Mechanical and physical specification of limestone is shown

in below:

|

Physical & Mechanical

spec. |

quantity |

Classified group |

Method of test |

|

Maximum water absorption (wt.%) |

12 |

Low |

ASTMC97 |

|

7.5 |

Medium |

|

3 |

High |

|

Minimum spg. (kg/m³) |

1760 |

Low |

ASTMC97 |

|

2160 |

Medium |

|

2560 |

High |

|

Minimum compression (Mpa)

|

12 |

Low |

ASTMC170 |

|

28 |

Medium |

|

55 |

High |

|

Module of elasticity(Mpa) |

2.9 |

Low |

ASTMC99 |

|

3.4 |

Medium |

|

6.9 |

High |

|

Min.

grinding (hardness) |

10 |

All

classes |

ASTMC241 |

Marble group:

This group covers

the wide range of rocks with different types of compositions

and textures. Therefore, from the economical point of view,

rocks with high content carbonate to low carbonates can be

classified in this group. Most of the marbles have

intermingled textures with quasi-crystalline minerals to 5mm

grains. Onyx, as a transparent calcite, with various colors,

belongs to this group. In addition, all dense and polished

limestone can be supplied as a marble stone.

According to ASTM503-97, marble decorative and building

stones are classified into four groups: Calcite, Dolomite,

Serpentine and Travertine.

Mechanical and physical specification of marble stone is

shown in below:

|

Physical & Mechanical

spec. |

quantity |

Classified group |

Method of test |

|

Maximum water absorption (wt.%) |

0.2 |

In

all four groups |

ASTMC97 |

|

Minimum spg. (kg/m³) |

2595 |

Calcite |

ASTMC97 |

|

2800 |

Dolomite |

|

2690 |

Serpentine |

|

2305 |

Travertine |

|

Minimum compression (Mpa)

|

52 |

In

all four groups |

ASTMC170 |

|

Module of elasticity(Mpa) |

7 |

In

all four groups |

ASTMC99 |

|

Min.

grinding (hardness) |

10 |

In

all four groups |

ASTMC241 |

|

Min.

bending stress(Mpa) |

7 |

In

all four groups |

ASTMC880 |